Over the past 70 years WIKA has built a reputation as a renowned partner and competent specialist for any task in the field of measurement technology. On the basis of steadily growing efficiency, innovative technologies are applied when developing new products and system solutions. The reliability of the products and the readiness to face all challenges of the market have been the key factors for WIKA to achieve a leading position in the global market.

Pressure gauges from WIKA – market leader since 1946

Our pressure gauges (mechanical pressure measuring instruments) for gauge, absolute and differential pressure have been proven millions of times over. For the optimal solution for the widest range of applications, there is a choice of measuring systems in Bourdon tube, diaphragm element and capsule element technologies. The pressure gauges cover scale ranges from 0 … 0.5 mbar to 0 … 6,000 bar and indication accuracies of up to 0.1 %. For the various requirements in industrial and process instrumentation there are pressure elements from copper alloys, stainless steel or special materials.

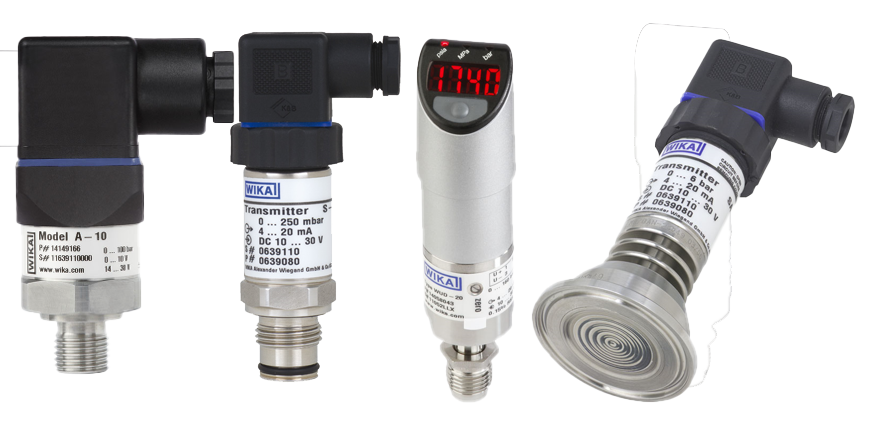

High measurement accuracy with process transmitters

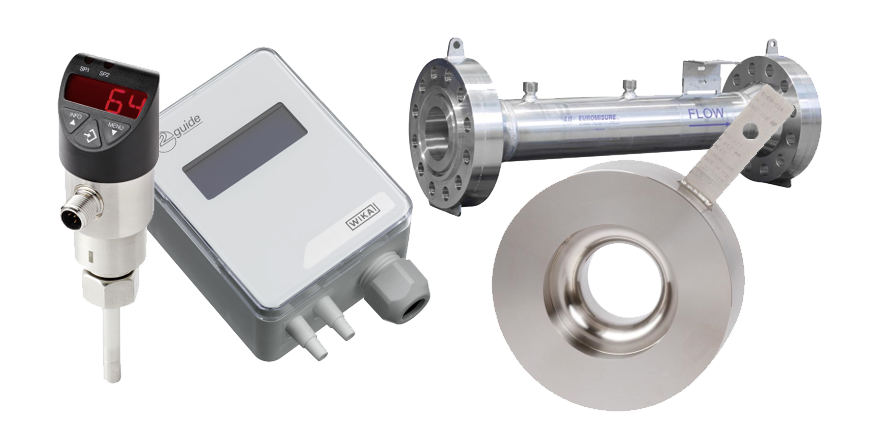

Process transmitters differentiate themselves from pressure sensors through their increased range of functionality: They feature integrated displays, offer high measuring accuracies and freely scalable measuring ranges, communicate via digital bus signals and can be delivered with a multitude of case variants and also worldwide Ex approvals. Through connection to diaphragm seals, they are also suitable for the harshest operating conditions.

A pressure sensor (pressure transmitter) converts the physical quantity 'pressure' into an industry-standard signal. Our portfolio covers a wide spectrum of pressure sensors: For refrigeration and air-conditioning applications, for the food industry, mobile working machines, medical gases and the semiconductor industry, special versions are available. The pressure sensors offer accuracies from 0.05 %, measuring ranges from 0.05 bar up to 15,000 bar, digital interfaces such as CANopen and IO-Link and also various international approvals, including for hazardous areas.

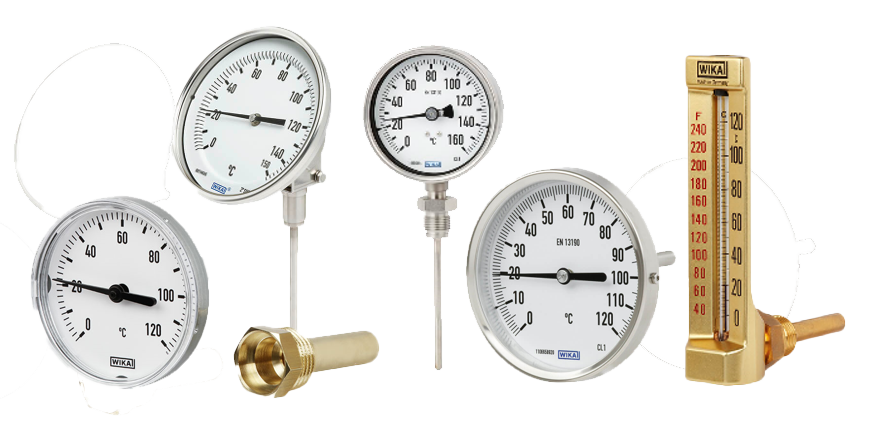

Our dial thermometers work on the bimetal, expansion or gas actuation principle. This enables scale ranges of -200 to +700 °C in different class accuracies, response times and resilience to environmental influences. Diverse connection designs, stem diameters and individual stem lengths enable a flexible measuring point design. Dial thermometers with capillaries are particularly versatile. All thermometers are suited for operation in a thermowell if necessary.

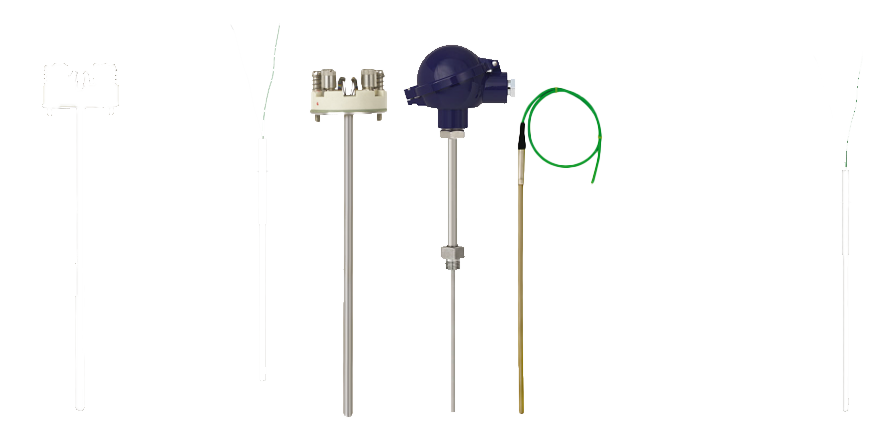

Thermocouples for temperature measurement up to 1,700 °C

Thermocouples generate a voltage directly dependent on temperature. They are particularly suited for high temperatures up to 1,700 °C. Instrument designs from mineral-insulated sheathed cable are very resistant against extremely high vibration loads (depending on instrument model, sensor element and wetted materials). The accuracy classes 1 and 2 apply for thermocouples in accordance with IEC 60584 as well as the standard and special classes in accordance with ASTM E230.

Resistance thermometers with Pt100/Pt1000 resistance

Resistance thermometers are equipped with platinum sensor elements which change their electrical resistance as a function of temperature. In our range of products you will find resistance thermometers with connected cable as well as versions with connection head. A temperature transmitter can be installed directly in the connection head. Resistance thermometers are suitable for applications between -200 ... +600 °C (dependent on instrument model, sensor element, accuracy class and materials coming into contact with the medium). Accuracy classes AA, A and B apply to all resistance thermometers. They are available with a tolerance value to IEC 60751.

High-quality temperature transmitters from WIKA

Temperature transmitters convert the input signal from a wide range of sensors, such as resistance sensors and thermocouples, but in some cases also from potentiometers, into a standardised output signal (e.g. 0 ... 10 V or 4 ... 20 mA). With digital temperature transmitters, the sensor type and the measuring span can be freely configured, along with many further options such as the error signalisation or a measuring point identification.

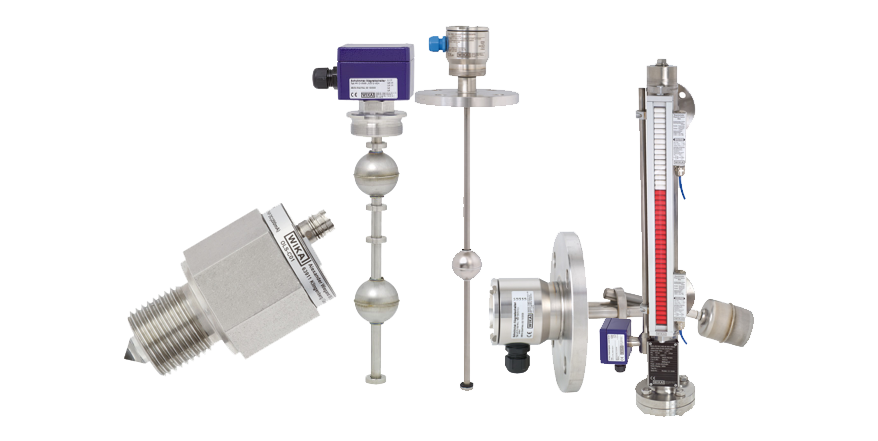

The detection is widely independent of physical characteristics of the liquids such as density, dielectric constant, conductivity and refractive index. These instruments are notable for their compact design and do not feature any moving components. With a measuring tip from borosilicate or quartz glass, and robust stainless-steel cases, they offer a high media compatibility.

For each flow measurement the right flow switch

Flow switches are used for the display and monitoring of the flow of liquid and gaseous media. The instruments feature a high switching accuracy and functional safety, low switch hysteresis and continuous switch point setting by the operator. The wide selection of WIKA flow switches also includes viscosity-compensated models and ATEX-certified instruments for use in hazardous environments.

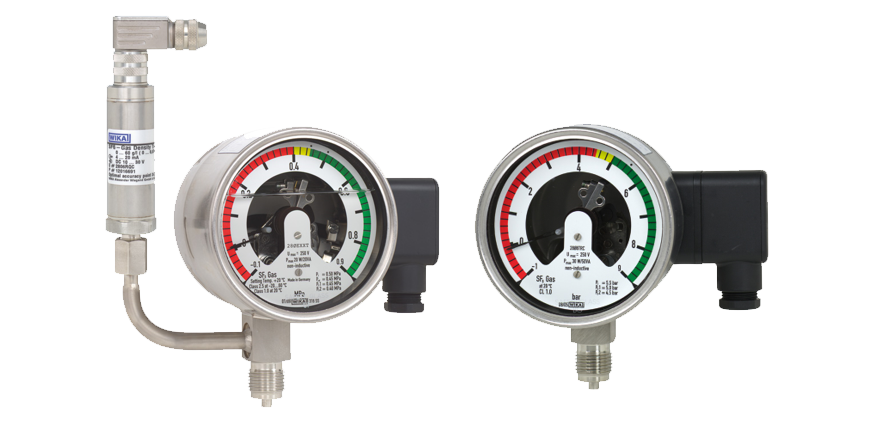

Sulfur hexafluoride (SF6) is an extremely effective electrical insulator for medium- and high-voltage switchgear. For proper insulation, gas density must remain within certain levels. Furthermore, as SF6 is a potent greenhouse gas, it must not escape into the atmosphere. An SF6 gas density monitor warns operators of dropping levels that indicate contamination and/or leaks. WIKA’s SF6 gas density monitors are temperature compensated and hermetically sealed to shield measurements from atmospheric pressure fluctuations and differences in mounting level. Manufactured entirely from stainless steel for reliability and long life, they are fitted with up to three alarm contacts to provide advance warnings when pre-defined limit levels are reached.

Precise calibration instruments are the starting point for resolving your test requirements, even though they are only one component of a high-performance calibration system. From our extensive product range, we can design you a complete and individual solution with: