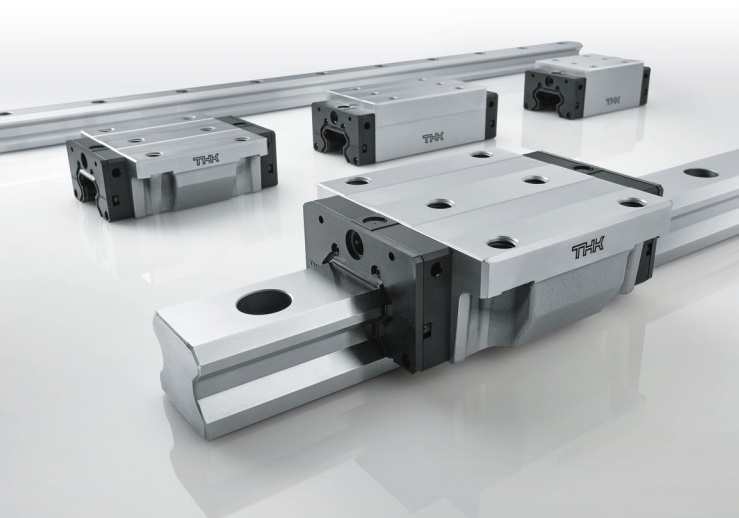

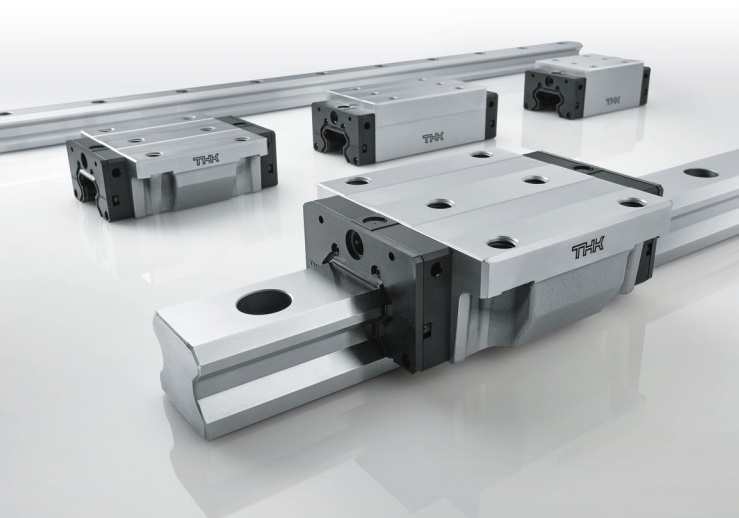

Features 1 : Ultra-High Rigidity and Ultra-Heavy Loads

The HRX is an LM Guide that uses rollers as a rolling element for higher rigidity. Also, compared to our existing roller products, we have extended the overall length of the LM block and increased the number of load-bearing rollers to achieve improved static load rating.

Features 2 : 4-Way Equal Load

On the HRX, each row of rollers is arranged at a contact angle of 45° so that the LM block receives an equal load rating in all directions (radial, reverse radial, and horizontal directions), ensuring high rigidity in all directions.

Features 3 : LM Blocks and LM Rails Available for Individual Sale

The HRX lineup features interchangeable products that can meet specifications by freely combining LM blocks and LM rails of the same model number. See p. 15 for details.

Structure and Features

Caged Ball LM Guide Actuator model SKR is a compact actuator that has a inner block consisting of LM blocks and a ball screw nut integrated inside a U-shaped outer rail. In addition, this model achieves high speed operation, lower noise and longer-term maintenancefree operation by using ball cages in the LM Guide units and the Ball Screw unit. (A ball cage is used only for the LM guide section of models SKR20 and SKR26 and the ball screws are fi tted with QZ lubricators.)

The Ball Spline is a recirculating ball guide. This innovative product uses a ball bearing running in a shaft groove. The resulting contact allows for high load capability than conventional linear bushings with the added advantage of torque transmission while undertaking the linear movements.

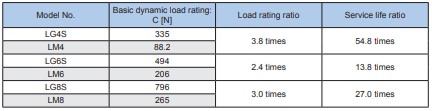

Since model LG has 4 rows of circular arc grooves (raceways), it does not need a mechanism to prevent the outer tube from rotating. In addition, its load rating is much larger than Linear Bushing model LM with the same dimensions. Therefore, replacing the Linear Bushing with the Guide Ball Bushing will reduce the size and cost of the guide unit and extend the service life.

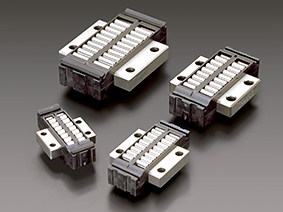

Model ER is a slide unit using a stainless steel plate that is precision formed, heat-treated and then round. It has a structure where balls roll between the V-shaped grooves machined on the outer rail and the inner block to allow the system to slide. It is an ultra-thin, lightweight unit in which the balls circulate in a ball case incorporated in the inner block to perform infi nite straight motion. This model is used in extensive applications such as magnetic disc devices, electronic equipment semiconductor manufacturing equipment, medical equipment, measuring equipment, plotting machines and photocopiers.

The Linear Ball Slide is a highly corrosion resistant slide unit that has an extremely low friction coeffi - cient because stainless steel balls roll on four stainless steel needle roller raceways that are hardened and ground. In addition, model LSP has a pinion gear in the center and a rack on the base to prevent the cage from slipping. A ball slide equipped with a cylinder model LSC has a cylinder for drive in the base to downsize the system and reduce the space and the weight Its components are all made of stainless steel, which is highly corrosion resistant. Furthermore, since its inertia is small, the slide system is highly responsive to high speed. By simply securing the Linear Ball Slide on the mounting surface, the user can easily achieve a linear guide mechanism. Thus, this slide system is optimal for locations requiring high accuracy, such as optic measuring machines, automatic recorders, small electronic-parts assembling machines, OA equipment and its peripherals.

In the LM Roller, dual rollers assembled on the circumference of the precision-ground, rigid raceway base travel in infi nite circulation while being held by a retainer. A center guide integrated with the raceway base is formed in the central part of the loaded area of the raceway base to constantly cor- rect skewing of the rollers. This unique structure ensures smooth rolling motion. The LM Roller is used in applications such as the XYZ guide of NC machine tools, precision press ram guides, press dies changers and heavy-load conveyance systems.

For the Flat Roller, precision rollers compliant with JIS B1506 are installed in a thin, steel plate cage, which is formed into an “M” shape for improved rigidity and light weight. The pockets of the cage are designed to prevent the rollers from falling out. The Flat Roller is sandwiched between two race- ways, so it moves half the distance traveled by the table. For example, if the table moves 500 mm, the Flat Roller moves 250 mm in the same direction. The Flat Roller is optimal for large machine tools such as planer, horizontal milling machines and cylindrical grinding machines, and for locations requiring high accuracy such as surface grinding machines, cylindrical grinder and optic measuring machines.

Slide Pack model FBW-XR is an LM system in which a precision press molded slider that contains balls performs infi nite straight motion. Used in combination with a slide rail, the Slide Pack achieves lightweight and compact design and smooth straight motion. This product is optimal for light-load slide units in products such as photocopiers, tool cabinets, elec- tronic equipment cabinets, automatic vending machines, machine tool slide covers, cash registers and curtain walls.

Slide rails are low-price fi nite linear guides made out of precision roll-formed steel plates. Suitable for various purposes because they are thin, compact, and easy to mount. Slide rails can be used in a wide range of applications such as photocopiers, measuring instruments, telecommu- nications equipment, medical equipment, automatic vending machines, and various types of offi ce equipment. The Model FBL slide rail has two rows of ball bearings placed between an inner rail and an outer rail that have been roll-formed out of steel plates. The ball bearings are evenly spaced by a precisely press-molded retainer, eliminating friction between the bearings and achieving a smooth sliding mechanism.

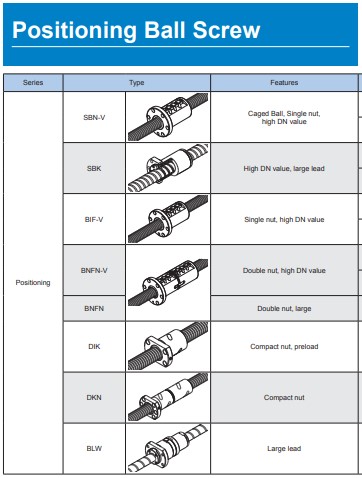

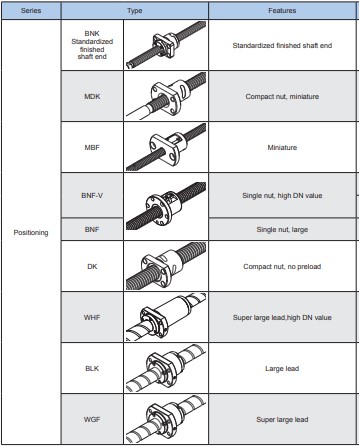

The Ball Screw is a high-efficiency feed screw with the ball making a rolling motion between the screw axis and the nut. Compared with a conventional sliding screw, this product has drive torque of one-third or less, making it most suitable for saving drive motor power.