General purpose, compact, modular, inline reducers and gearmotors offering easy installation of output chains and sprockets; high shock load capacity; durability; and wide ratio ranges.

The Sumitomo Cyclo® drive is unsurpassed by any other inline drive available in the market today.

Cyclo's unique epicycloidal design has advantages superior to speed reducers that use common involute tooth gears. Cyclo components operate in compression, not in shear.

Unlike gear teeth with limited contact points, a Cyclo has two-thirds of its reduction components in contact at all times. This design enables Cyclo speed reducers and gearmotors to withstand shock loads exceeding 500% of their ratings, and provide exceptional performance, reliability and long life in the most severe applications.

| Sizes | 34 sizes |

| Torque | 24 Nm to 68,200 Nm |

| HP | 0.10 to 235 HP |

| Ratios | 3:1 to 119:1 (single) 121:1 to 7569:1 (double) 8041:1 to 658,503 (triple) |

| Motor Standards | CE,CCC,IEC,JIS,NEMA,UL,CSA |

Prest NEO® Innovative product with unparalleled benefits is most favored choice for Food & Beverage manufacturing application installments

Compact new design Prest NEO® gears are designed with high contact ratio and high stiffness to lower the noise. Triple lip seal protection oil leakage design is excellent choice for food & beverage manufacturing application installations.

Key features:

| Sizes | 11 |

| Torque | 77 |

| Horse Power | 0.1 kW to 2.2 kW, 4 poles |

| Ratios | 15 (3:1 to 200:1) |

| Mounting | Foot, Flange |

| Motor Standards | IEC |

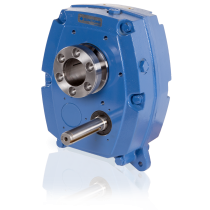

Helical Shaft Mounted Speed Reducer (HSM) is one of the popular products in our portfolio. It is also available with CEMA screw conveyor drive option.

Helical Shaft Mounted Speed Reducer (HSM) features patented keyless, steel Taper-Grip® bushing for easy mounting and as well as traditional keyed hub option. The key features of HSM include

| Power | 0.18 kW to 220 kW ¼ HP to 300HP |

| Ratio | 5:1, 13:1, 20:1 and 25:1 |

| Sizes | 015 to 608 |

| Bore Sizes | Metric: 30mm to 190mm Inch: 15/16" to 6 1/2" |

| Mounts | Horizontal, Vertical and Motor mount configurations |

| Lubrication | Oil lubrication, synthetic lubrication (optional) |

| Housing | Cast iron split-case construction |

| Screw Conveyor Option | CEMA Standards |

| Accessories Available | Taper Grip Bushing, Motor Mount, Back Stop, Torque Arm, Belt Guard, Belt & Pulleys, Breathers, Taconite Seals, Screw Conveyor Adapter Kit, Screw Conveyor Seal Kit |

| Bearings | Ball Bearing and Taper Roller Bearing options |

The Hyponic® features a compact modular housing, patented Hyponic gear technology, maintenance-free grease lubrication, high efficiency operation, and universal mounting.

The Sumitomo Hyponic® gear motor represents 60 years of excellence in the design and manufacture of premium gearing solutions. With millions of Hyponics currently in service, the product features a compact, modular housing, maintenance-free grease lubrication, and high efficiency operation. Options include C-face quill design; unique FKM antimicrobial, multi-lipped rotary output seal; corrosion resistant, stainless output shaft and hardware; and synthetic NSF H-1, food-grade lubricant. NSF51 antimicrobial powder coating makes Hyponic the ideal choice for food, beverage, baggage handling, electronics and pharmaceutical industries..

| Ratios | 5:1 to 1440:1 |

| HP | 0.0932 to 11.1899 Kw 1/8 to 15 HP |

| Electrical | 230/460 VAC, Single and 3-Phase |

| Housing | Lightweight, corrosion-resistant aluminum |

| Mounting | Flange, Bolt-on Feet |

| Shafts | Hollow, Solid |

| Input | Quill, C-Face Adapter or Integral Motor |

| Motor Standards | CE,CCC,JIS,NEMA,IEC |

| Lubrication | Grease, no maintenance |