Inverter FUJI MINI (FRN-C)

With its rich functionality, compact design, simple operation, and global compatibilty, the new FRENIC-Mini C2 elevates the performance of a wide range of devices and equipment - including conveyors, fans, pumps, centrifugal separators, and food processing machines - to give you the system integration, energy efficiency, reduced labor, and lower overall costs you're looking for.

High Performance and Multipurpose

●Dynamic Torque Vector Control System

Fuji Electric original dynamic torque vector control system is known for its top-of-the line performance, delivering stabile torque output even at low speeds. This feature has a wide range of applications, including conveyors and high-inertia loads that demand high starting torque.

●Slip Compensation shortens setting time

The slip compensation controller works with voltage tuning for even more accurate speed control at low velocity. This reduces speed control variability and stabilizing creep speed for more accurate stopping in conveyors and similar equipment.

●Fastest CPU Processor in its Class

Advanced CPU processes data at twice the speed of our current model

Full Compatibility and User Friendly Design

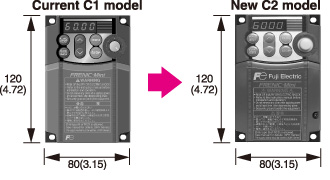

Note: Three-phase 200V 0.1–0.75kW dimensions shown (mm(inch))

| External dimensions | Interchangeable |

|---|---|

| Installed dimensions | Interchangeable |

| Number of terminals | Same for both main circuit and controllers |

| Terminal position | Compatible terminal wire length |

| Function codes | Compatible function codes |

| RS-485 communication | Shared communications protocol |

Easy Operation and Maintenance

Delivers all the usability of the C1. Provides volume of frequency and the same ease of operation as the current model.

Optional USB keypad available. Enhanced PC loader connectivity.

·PC loader software available as a free download

| Function | Description |

|---|---|

| Mock malfunction | Select a function to set off a mock alarm |

| Number of startups | Count the total number of ON/OFF run cycles |

| Cumulative motor running time | Monitor motor run time |

| Total power | Set to measure total power consumption |

| Trip history | Saves and displays information on up to four past trips |

Energy Optimization

●Optimum Energy Control

Motor tuning minimizes power loss

●PID Control Function

Permits motor operation while controlling temperature, pressure, and flow rate without the use of a temperature controller or other external device

●Cooling Fan ON/OFF Control Function

The cooling fan can be switched off when the fan or pump is not running to reduce both noise and energy consumption

●Synchronous Motor Control

Use of sensorless synchronous motor control together with the motor can reduce energy consumption